If you want to be remembered in the shoe world, you need to break the mold. Converse was one of the first brands to popularize rubber footwear. Adidas made waves in the mid-20th century with its low-cut models, starting with the Gazelle and leading to Stan Smith. Nike introduced the waffle iron outsole, which led to innovations for running shoes and beyond. Vans developed the iconic Era design specifically to cushion the feet of skateboarders.

For Keen, it was a toe bumper.

Founded in 2003, Keen is a family-owned, Portland-based brand (although its roots are in California) that made a name in the footwear space by protecting your toes. The flagship design, the Newport sandal, stood out from other options with its sturdy rubber cap at the front, which encouraged wearers to go on outdoor adventures without worrying about stubbed toes. This toe bumper has factored into the brand’s now vast lineup, which includes work boots and casual footwear. According to the brand, over 10% of people who have purchased at least one pair have actually owned over 10 pairs of Keen shoes.

However, Keen is also a humble brand. Sure, the toe bumper is innovative. After experiencing it firsthand with a pair of boots, I appreciate the support it offers, but the brand goes beyond protecting one’s toes — the company makes it its mission to protect the environment as well.

In the 17 years since its inception, Keen has crafted a company around a focus on sustainability. We’re not just talking about making workspaces greener and ensuring that employees recycle (although Keen certainly does both and the story behind the buildout of its Portland headquarters is worth its own deep dive).

Keen dissects its supply chain. Every material source is analyzed for its environmental impact. While the team hasn’t reduced the company’s carbon footprint to zero, they are damn determined to get as close to that as possible.

I was invited to tour Keen’s headquarters and factory in Portland to better understand how the shoes are crafted and with what.

Quality Is Key to Production

A shoe company has to be “audacious with a reason,” Chris Pawlus, Keen’s Vice President of Design and Innovation, tells The Manual. That reason is sustainability and a mission “to bring innovation to the consumer faster,” he says.

But first, you have to make the shoe.

Seems simple enough, right? You design a shoe, make it, then people put them on their feet. But it really starts with a problem.

During my tour of Keen’s Portland facilities, I heard a lot about problems – but what kind of problem is Keen trying to solve? According to one team member, “the foot is the client.”

With the original Newport, the problem was stubbed toes. “The toe bumper is not a fashion statement, but it is why we are here today,” explains Pawlus. That same mindset applies to all of Keen’s shoes. For example, the Utility line of work boots is arguably the second most recognizable offering from the brand. That same problem of foot protection was solved by Keen’s ability to “think of a worker like an athlete,” according to Pawlus.

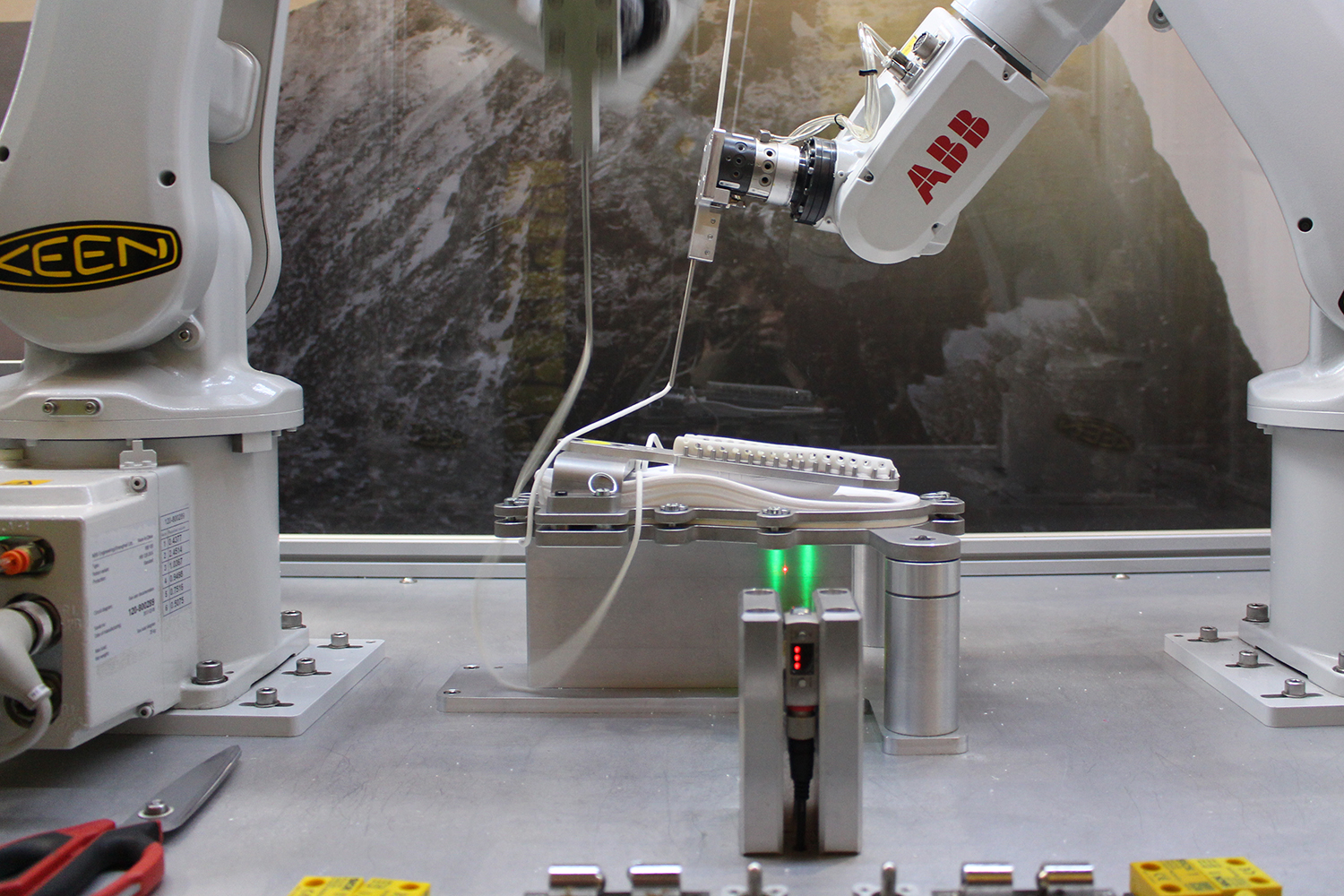

The shoe-making process is obviously a lot more complicated than the three-step process. The more steps that Keen creates, the more it can control the quality of a product. For example, one team uses 3D printing to bring digital designs to life with compostable plastic without sending them to factories for samples. While the plastic material isn’t suitable for walking, it allows the team to skip the middleman of prototype production, explore ideas in real-time, and not worry about creating shoe waste.

Keen also has the Maker’s Lab, where more practical prototypes are crafted from a library of different materials. When the team is satisfied with a design, the prototypes are broken back down by their components and sent to the correct facility for production. The place that makes the soles isn’t necessarily the place the cuts the leather for the uppers, which is where Keen’s impressive supply chain comes in (more on that in a moment). The various production facilities in Cambodia, China, India, Mexico, the Philippines, Thailand, and, of course, the United States allow the team to control more of the process.

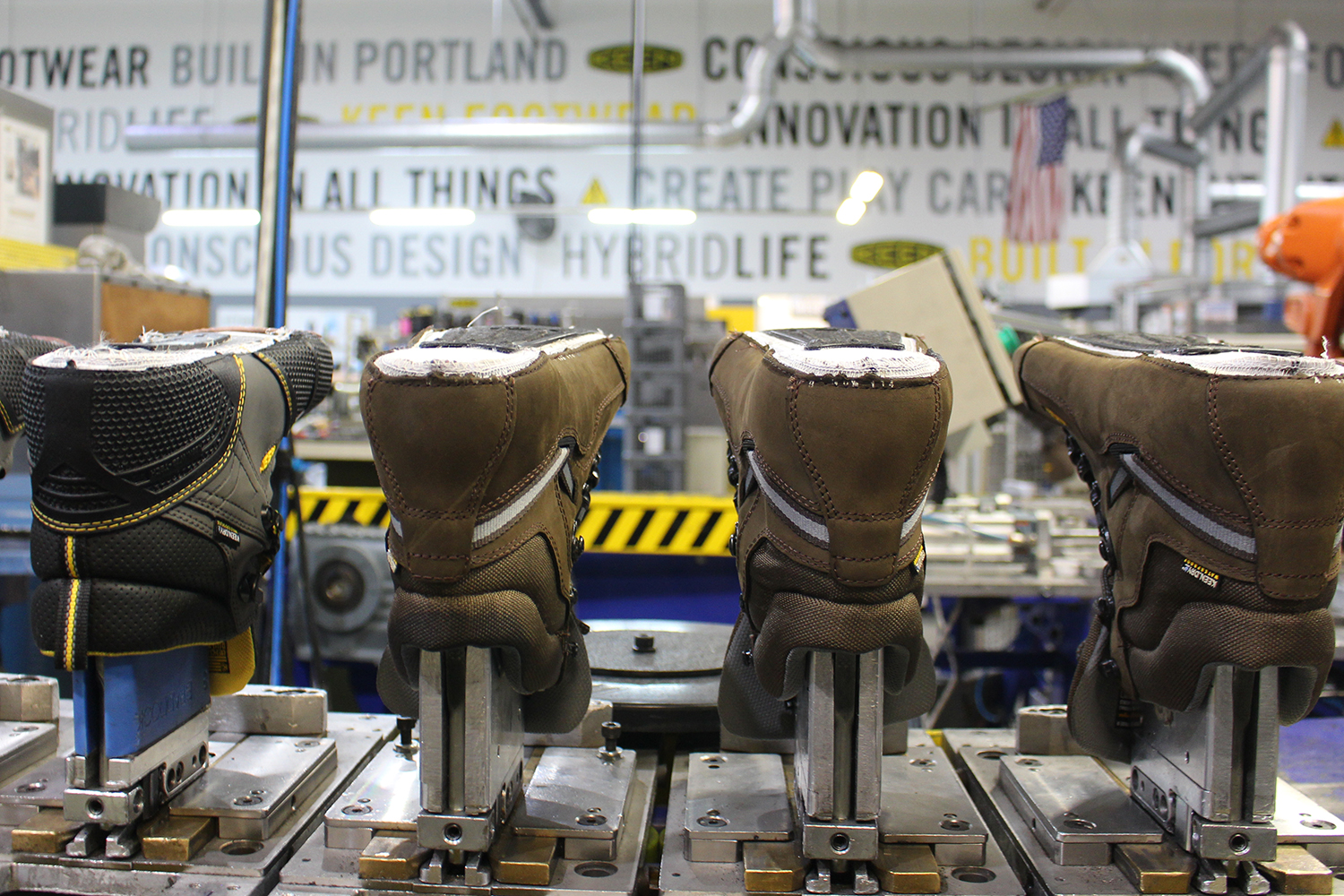

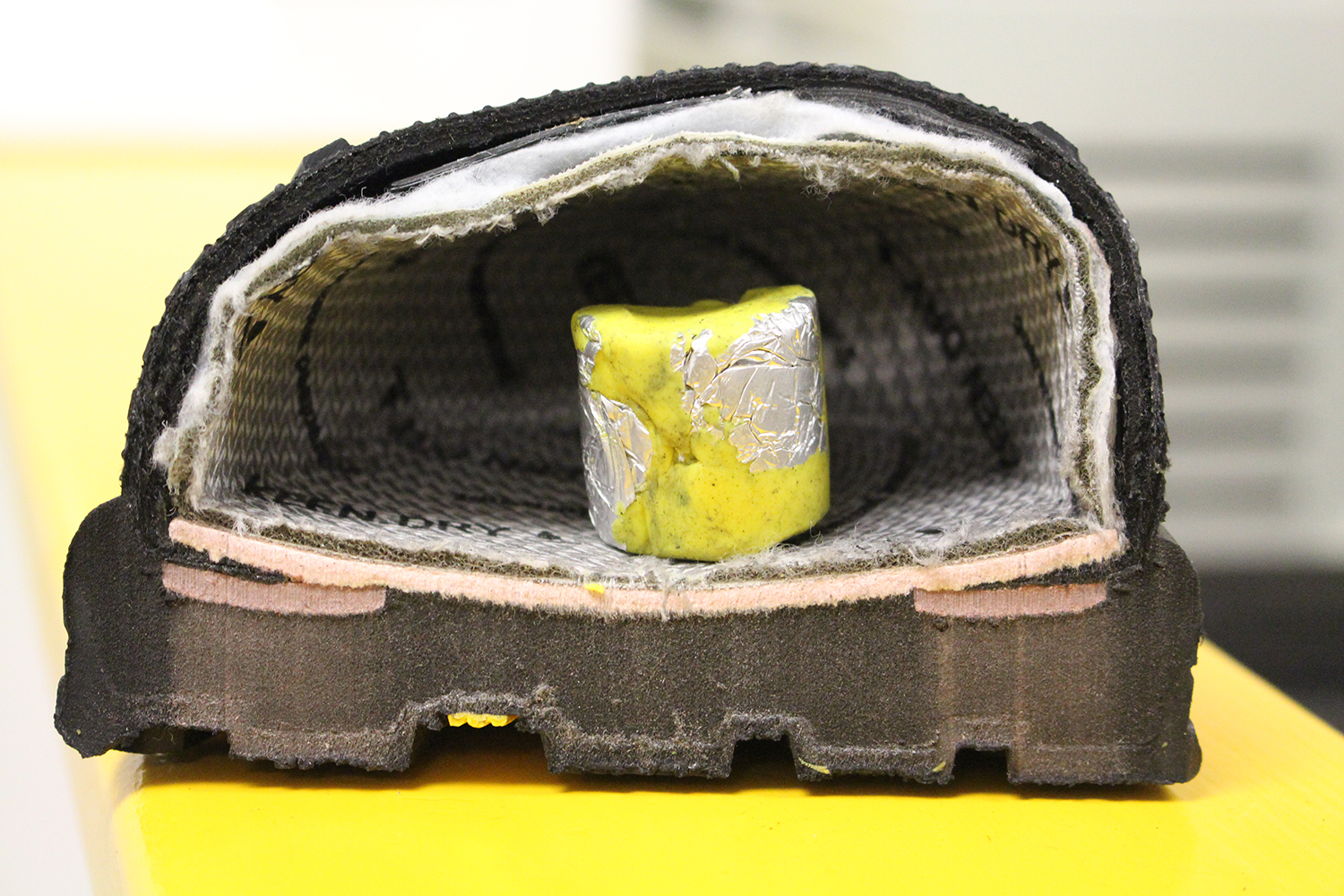

Let’s look at one slice of that process: Keen’s American Built collection. On the floor of the Portland factory, which opened in 2010, you will see multiple shoe sizes, colors, and styles at various stations. Shoes are randomly selected to go to the Quality Lab, where they are ruthlessly tested for flex, the ability to handle sudden downward force, and waterproofing.

Quality is key for any product but especially important for a shoe, since it helps hold your body upright all day. When speaking with Don Wicks, the U.S. Plant Manager, he puts that quality in the perspective by referencing longevity. When you have a quality product, you don’t throw it away – you hold on to it or recycle it. Looking at the bigger picture, the Environmental Protection Agency estimates that the U.S. created 12.8 million tons of clothing and footwear in 2017. However, only 1.7 million tons were recycled.

Keen’s quality is endemic to its mission to protect the environment. The production crew is focused “on making a good product that’s environmentally sustainable,” says Wicks. When we can be involved on the factory floor, “we can control every part of that.”

Consciously Creating a Better Supply Chain

So, we’ve got the philosophy: Make shoes that solve problems for people who work and play hard.

We’ve got the design and production process: Involve the team in every step to ensure quality.

But like a great dish, it really comes down to the ingredients. You can’t have a delicious lasagna if you don’t source ripe tomatoes, fresh cheese, and handmade pasta.

The bottom line for the brand is to ensure that the supply chain – where the shoe materials are sourced – is of the same high quality as the rest of the production line.

Where do you start? The first step is to understand each individual component. You have to grasp how a cow is connected to the leather in your boot.

According to Kirk Richardson, Keen’s Supply Chain Expert, and Chris Enlow, the Corporate Responsibility Director, it boils down to two things: control (which we’ve already seen demonstrated in how the shoes are made) and education.

“The supply chain is multilayered,” Richardson tells The Manual. “That’s been the most interesting work for us is figuring out where stuff came from.”

“We focus on the ‘why.’ A lot of these things aren’t exciting. They’re very cut and dry … very transactional,” says Enlow. “There are 50 different companies represented in that shoe. If you can’t get people educated and excited about the ‘why,’ you can’t get them” to understand the effect their shoe decisions have on the environment.

Keen’s “Consciously Created” campaign highlights “why” Keen made certain changes to its supply chain:

- Keen developed an eco-friendly anti-odor that ditches harsh chemicals in favor of probiotics – yes, those same little microbes that help you regulate your stomach – to make sure your shoe smells less, well, smelly. You know that new car smell? Products can sweat like humans, giving off a chemical odor. The company was concerned about the health effects of the anti-odor chemicals, so they found a way to replace it with a biologically based solution.

- All of the leather used in the shoes is LWG-certified (Leather Working Group). Keen only works with tanners that have a closed-loop water treatment process. What does that mean? Well, tanning leather requires a ton of water, which is contaminated in the process. A closed-loop system prevents that water from being reintroduced into the environment and recycles it back into the tanning process.

- In 2019, the shoes became 95% free of perfluorinated chemicals (PFCs), a common substance used for waterproofing gear. The Keen website describes it best: “These compounds are suspected carcinogens and degrade very slowly in the environment, so we’ve switched to alternative chemistry that’s safe and performs just as well.” Being PFC-free is out of scope for footwear so you can’t get credit it for it in the public space. But Keen does it anyway.

When I ask what Keen could teach other footwear makers, one word comes to mind:

“Curiosity,” says Kirk.

For example, polyurethane is an organic polymer that can be found in anything from insulation to condoms. At Keen, it’s used for the midsole in some shoes because it’s extremely durable. However, it’s also made from oil, which we all know isn’t the most sustainable resource. The goal of team members like Enlow and Richardson is to find a replacement for an industry staple like polyurethane, which then forces the rest of the industry to rethink how they use materials. They aren’t trying to reinvent the wheel, but rather find a better way to make it.

“It’s looking at what we can do with new alternatives, then proving what it can do the marketplace, then incorporating it into our [products],” explains Enlow. “Polyurethane – I dream of a day that can be 100% bio-based.”

Toes to Tomorrow

It takes years of work to build something like this. But it all begins with the work they’ve done – begins, not pauses or ends. After spending time with the Keen team, from supply chain to shoe design to production, I felt that “begin” was an unofficial mantra. Why wait for another company to solve problems for both our feet and our planet when we can begin the process right here?

For context, my factory visit occurred when the Germany-based Adidas announced the closure of two facilities in the U.S. and Germany in favor of outsourcing to Asia.

Keen’s commitment to establishing a sustainable supply chain and a Stateside foundation for American-made footwear while other companies are looking to outsource isn’t just a statement. It’s a personal belief that starts at the top.

“[Keen is] not just doing it because it’s cool,” says Enlow.

“[We’re] concerned about the footprint on the world that we operate within,” Richardson finishes.

From where we’re sitting, it looks like tomorrow’s footprint is going to have a toe bumper.